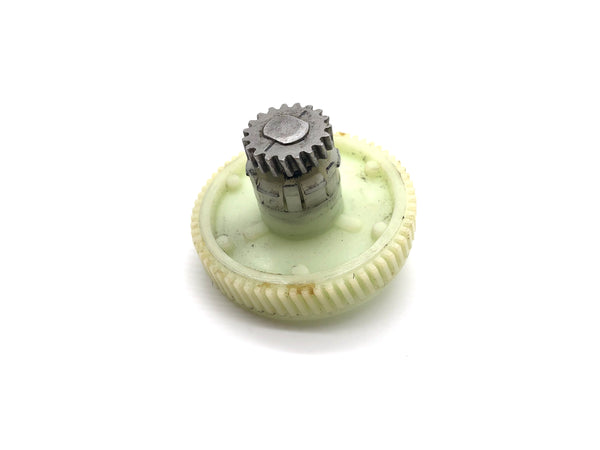

Dramatically simplified: Reproduction of the Smart 450 top sprocket

A common weak point in the Smart 450 is the pinion that drives the convertible top. This often breaks and is often the cause of a defective convertible top that no longer runs optimally.

The original sprocket is a laboriously produced replacement part, as it is a plastic part with several integrated metal components. This is also reflected in the price, which often makes this convertible top sprocket very high-priced and expensive.

Reconstruction and reproduction of the Smart 450 sprocket

In order to develop a cost-effective and future-proof solution, we first reconstructed the pinion, slightly adjusted the geometry and then re-manufactured it in an optimized material in a much simplified manner.

The result:

Except for the cylinder pin, which sits in the back of the sprocket, the smart sprocket is printed entirely from one material. The adapted geometry makes replacing the pinion even easier, so that the old pinion can simply be removed from the engine and the new pinion can be inserted quickly and easily.

Here you can go directly to the finished product: Smart 450 top sprocket